|

ROBOTIZATION AND AVTOMATIZATION IN DIFFERENT PRODUCTIONS |

|

EQUIPMENT FOR

|

|

ATEX FILTERS |

|

METAL SURFACE CLEANING MACHINES |

|

STANDARD SHOTBLASTING MACHINES ON STOCK |

|

Модернизация дробеметных установок |

|

TUNNEL OVERHEAD

|

|

SIAPRO TEST CENTER

|

|

SYSTEMS FOR AVTOMATIZATION |

d.thumb-540x164.jpg) |

HUGE MACHINES AND LINES FOR SHOTBLASTING AND PAINTING |

|

SMART &

|

|

Транспортная система |

|

SHOT BLASTING MACHINES WITH ROTATING HOOK |

|

ROBOTIZATION AND AVTOMATIZATION IN DIFFERENT PRODUCTIONS |

Инжиниринговые проекты под ключ

Siapro осуществляет разработку инновационных инжениринговых проектов в области литейного производства, металлургии, дробеметной очистки и подготовки металлических поверхностей, машиностроения и смежных проектов. Мы осуществляем весь спектр инжиниринговых услуг: консалтинг, проектирование, производство и поставка оборудования, монтаж и техническое обслуживание оборудования, оптимизация и модернизация оборудования.

Мы являемся международной командой квалифицированных консультантов, инженеров и технологов в области оборудования для литейных производств. Мы имеем хорошие знания и опыт, полученные на основе длительной работы в промышленности. Наши услуги отличаются и профессионализмом и качеством.

VIDEO Company presentation VIDEO Foundry Equipment VIDEO Shotblasting Machines

Наивысшие требования к дробеметной и механической очистке металлов

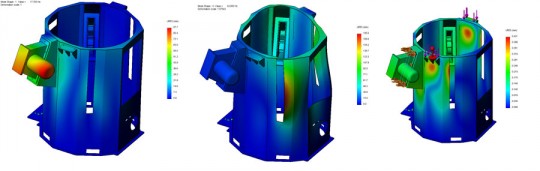

Благодаря нашей новой революционной технологии E-ECO CPMT для полного контроля процесса обработки металлов мы предлагаем высочайшее качество процессов и самые высокие требования к обработке металлов. Благодаря эффективному контролю, в сочетании с новой дробеметной турбиной E-ECO, и последнему поколению AAD-клапанов, для автоматической дозировки абразива, мы соответствуем самым высоким требованиям клиентов.

Стандартные дробеметные установки в наличии

E-ECO Siapro Высокоэффективные турбины – Разработка Siapro, Оптимизированный прайс (Базовый, Упрощенный, Специальное решение), Хорошая цена для предлагаемого качества и надежности конструкции

Подробнее ...

|

Renovation and expansion in progress at Siapro!Our building at our headquarters is getting a fresh new look - and we’re moving into upgraded offices in the future!We’re excited for this new chapter, with more space to grow, collaborate and innovate. |

|

Siapro Sports Afternoon!Siapro Sports Afternoon! As part of our Workplace Health Promotion initiative, we at Siapro enjoyed a pleasant sports-filled afternoon — we set off from the company for a hike to Široko, where we were greeted with a stunning view and delicious food.Together, we did something good for both body and mind, and further strengthened our team spirit! |

|

Street of the future in TolminAt the Street of the Future event in Tolmin, we introduced young people to the professions of the future. We took part in an event aimed at bringing the world of crafts and entrepreneurship closer to the youth. A total of 320 students from six primary schools in the Soča Valley, Kanal, and Brda were introduced to 17 professions that are crucial for our region today and in the future.At Siapro, we were pleased to present the professions of mechatronics and electricalengineering, opening the doors of modern technology and innovation to the younger generation. |

|

Stock machines Siapro for a good priceRobust machines and very good quality, quick delivery. Contact us at nejc.rutar@siapro.si |

|

Designing shotblasting machines in SiaproThe shotblasting machine design office at Siapro reflects a focused environment where creativity meets industrial precision. The team demonstrates a strong commitment to producing high-quality machinery. |

|

Our Offer Includes Custom-Made ConveyorsAt our company Strojrem from Siapro Group, we have been designing and manufacturing custom-made conveyors for many years, tailored to the specific needs of each client. Our extensive experience and high production capacity enable us to deliver even the most demanding projects quickly and with high quality. We produce various types of conveyors for different industries, always ensuring reliability, efficiency, and long service life. Trust Strojrem – the expert in tailor-made solutions. Check more about our transporters here |

Постая, 9

5216, Мост на Сочи

Словения, Европа

Тел: +386 5 3841 632

E: info@siapro.si

Персональные контакты >

Подписывайтесь на нас

ПАРТНЕРЫ

|

|

|

.thumb-200x110.jpg) |

|

.thumb-200x110.jpg) |

|